You’d probably be annoyed if your boss dropped another month of work on your desk just as you wrapped up a huge project.

It’s a lot different when you’re a specialty aerospace contractor wrapping up work on a launch site and NASA asks you to hang around for four more weeks to take on another job.

When that happens, you celebrate.

In this case, as the installation of 14 liquid fueling facility (LFF) process piping skids wrapped up at the Wallops Island, Virginia launch site, NASA’s request was music to our ears.

“Wanna stay a little longer?”

NASA widens project scope to include stainless panels

If you haven’t read the in-depth case study about our fabrication and installation of 14 LFF process piping skids for this launch facility, do that first. Check it out here.

It was near the end of that project that NASA engineers decided to add four stainless steel control panels to the facility that would control and monitor volume, pressure and flow rate within the skids we’d just installed.

Once operational, the panels would allow NASA launch engineers to verify that fueling operations were proceeding as intended and provide advance warning in the event of a problem.

The stakes were high. The LFF at Wallops Island is responsible for prepping space missions that resupply the International Space Station and deliver both private and government satellites into orbit.

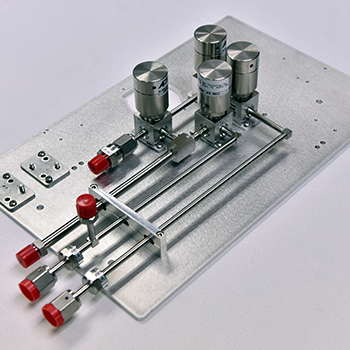

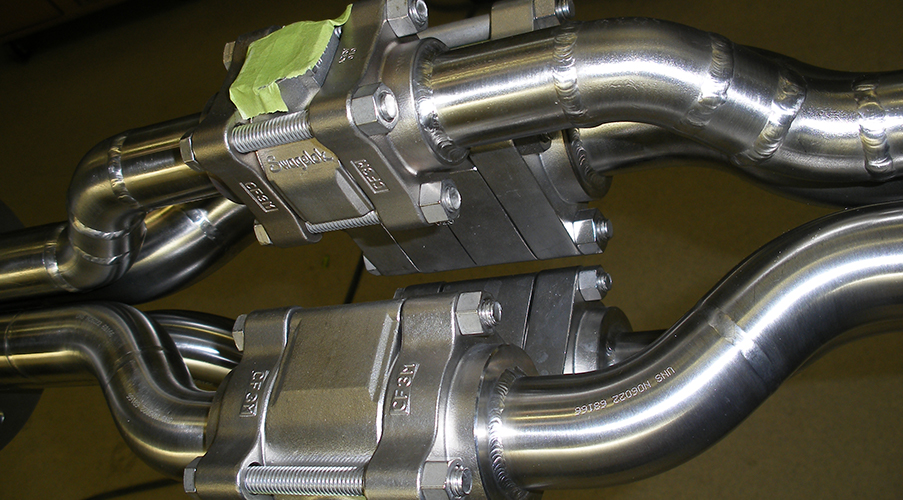

The schematics and specs NASA provided our team called for four control panels, each one made of 316L stainless steel tube and components mounted on 6061 aluminum plates installed near the LFF skids.

A 3’-by-4’ recirculation pump purge panel would keep fluid inside the system moving while the system was not in use. By not allowing fluids inside the pipe to sit stagnant, the risk of corrosion within the system is greatly reduced.

A 3’-by-4’ differential pressure purge panel allowed ground support engineers to keep differential pressure among the systems within specifications.

Two 4’-by-6’ pressure and instrument panels provided engineers with added visibility of conditions inside the system, reducing the risk of failure due to over- or under-pressure within the system.

Custom stainless steel control panel fabrication

Our team developed 3D CAD models of the panels for NASA’s inspection. Upon their approval, we began the custom fabrication of the panels. Much of the fabrication depended on our employment of tube bending and flaring equipment, repeating the strategy that had reduced equipment requirements and labor hours during the initial skid fabrication that preceded this project.

To match the facility’s existing panels, we applied a Tiger Drylac powder coat finish to the aluminum pieces before installing them with a combination of compression fittings, O-ring boss fittings, JIS 37˚ flare fittings and flare adapters, and MS and AN fittings.

After completing the panels, our fabrication team pressure tested the panels with National Institute of Standards and Technology (NIST) certified gauges and torque fittings to ensure compliance with customer specifications.

Finishing strong with in-house QA/QC

Our fabrication team turned this project around just four weeks after receiving the materials from the customer. That’s a fast delivery for panels of this complexity.

HPS’ in-house QA/QC capabilities contributed to finishing the project on NASA’s compressed timeline. The QA/QC process for aerospace piping projects is quite intensive. Any fabricator needing to engage a third-party provider to sign off on the work would probably not have finished a similar project on time.

But realizing a time savings was only one of many benefits of using this in-house capability:

- It is more expensive to retain third-party quality assurance

- Not many third-party providers in this discipline exist, so availability on short notice is no guarantee

- Third-party providers often face the learning curve of becoming familiar with fabricators’ internal processes and documentation methods

- Our in-house QA/QC personnel are intimately familiar with the weld types required for projects of this type — in other words, there was no learning curve

Working with HPS

HPS’ past experience on aerospace piping fabrication projects landed us on NASA’s Wallops Island launch site in the first place.

Proving we could deliver complex work on a tight deadline for this renowned customer landed an invitation to stay around a while longer.

That’s how partnerships are made.

Are you looking for something similar? Let’s talk about what’s on your project docket. Contact High Purity Systems now.

Contact High Purity Systems

Have a question about a piping challenge? Want to discuss an upcoming project? Let’s talk.