Manufacturers of all stripes know the struggle of meeting existing production obligations while also ensuring facilities are prepared to ramp up capacity in the face of growing demand.

So when new projects enter the pipeline, production managers walk the tightrope. If they fall down one way, future opportunities could slip away. If they fall down the other, existing obligations go unmet.

When the right specialty piping contractor is involved, no one falls down at all.

The challenge

The scenario above applied nicely to a semiconductor manufacturer near Washington, D.C. As demand for their products grew, it was clear in the spring of 2020 that they would need to increase production capacity.

Part of that expansion involved making upgrades to the facility’s UPW, RO/DI and reclaim water systems. That required fabrication and installation of 700 linear feet of new Schedule 10 316L stainless steel pipe. An added challenge was the customer’s directive that the project not cause delays to daily production and take up as little facility space as possible during installation.

High Purity Systems was chosen for the work based on its reputation for delivering quality work and its extensive prior experience with this customer.

The strategy

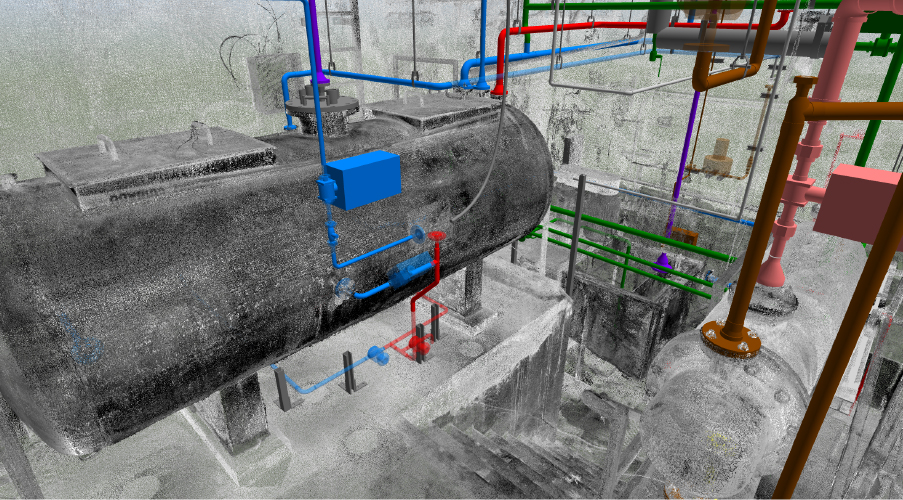

The first step for this project was to take accurate measurements of our workspace. Keeping in mind the customer’s requirement that production be maintained and that the presence of construction crews be minimized, we accomplished this by utilizing laser scanning technology.

Laser scanners shave many hours off the measuring process, and they do it with far better accuracy than other digital methods. (In fact, the laser scanner we use—a Faro S350—is accurate down to one millimeter at 350 meters distance!)

In this case, we scanned an area of roughly 3,000 square feet. This only took one person a single day to complete. Typically, hand measurements in a space this size require two people and takes them twice as long to complete.

After scanning, our team uploaded the point cloud created by the scanner into BIM software to generate a 3D model of the space. That model became our roadmap. It was so accurate, it allowed for custom shop fabrication of 90% of the project’s large-size piping in our Manassas, Virginia facility. (You can read more about the advantages of off-site fabrication in this in-depth guide.)

After items were fabricated, we shipped them to the site for installation on a just-in-time basis. No need for cumbersome staging of weeks worth of supplies. The only space we took up was for our crew, our tools and material for that day’s work. And, as another testament to the accuracy of our BIM model, every component we fabricated fit perfectly on the first try with no field modifications required.

The result

Accurate measurements, skillful shop fabrication and smart work from our install team contributed to an on-time delivery of this difficult project.

Successful delivery resulted in these key highlights:

- The facility maintained its rigorous production schedule through the duration of the project, resulting in no downtime or lost revenue

- Efficient, accurate laser scanning and BIM modeling contributed to faster fabrication and installation, saving time and money

- Off-site fabrication for this project generated a 20% cost savings for the customer

- The digital models generated on this project added new value for our customer by becoming an instrumental source of accurate facility information usable on future projects of any kind

This project demonstrates the benefits of partnering with the right specialty piping contractor, one who combines technical skill with project management expertise to keep complex projects on track and running smoothly.

What’s next on your facility’s project list? Do you think your space is a good candidate for laser scanning? We’d love to know more—contact us today.

And, you don’t have to have complex piping systems to utilize our BIM service. From large factories to storefronts to a residential basement, we offer it anywhere it can make a difference! Learn more here.

Contact High Purity Systems

Have a question about a piping challenge? Want to discuss an upcoming project? Let’s talk.